Level 3

Introduction to Dimensional Metrology

Course Outline

|

| Course Objective |

To provide hands applications on how to use shop level measurement equipment and to understand fundamental error sources and limitations applied to each. To provide insight on how to test the calibration on instruments using precision artifacts to ensure gages do not drift from their original calibration and induce an undesirable bias. Students will be introduced to how to repeatability and reproducibility (GR&R) of measurement instruments. |

| Course Length |

2 Day

(16-hours) |

| Course Content |

Precision Hand Tools and Hard Gaging |

| |

- Micrometers, calipers, indicators, pin & ring gages and thread gages

|

| |

Bench Top Measurement Instruments |

| |

- Height gages, bore gages, fixed gages and laser micrometers

|

| |

Surface and form instruments |

| |

- Profilometers, contour measurement, roundness and cylindricity systems

|

| |

Optical measurement systems |

| |

- Optical comparators, and toolmakers microscopes

|

| |

Introduction to coordinate measuring machines |

| |

- Manual & automatic CMMs, single point touch sensors & scanning sensors

|

| |

Methods for analyzing and interpreting data results |

| |

- Introduction to Gage Repeatability & Reproducibility (GR&R)

- Introduction to measurement error sources (variability & bias)

|

| |

Each session will include an overview of the tools followed by a demonstration of best application practices and a discussion of calibration issues and measurement variability & bias factors. Each session includes hands-on lab activity. |

| Targeted Audience |

Anyone requiring a foundational understanding of measurement systems used for measuring mechanical components and assemblies for proof of compliance versus process feedback. Specifiers and decision makers of engineering requirements and specifications as well as specifiers of manufacturing processes and measurement applications and anyone doing statistical analysis of design, manufacturing or measurement data. Engineers, designers, metrologists, technicians, machinists, toolmakers, designers, senior inspectors, senior technicians, statisticians and mechanical engineers at all levels. |

| Prerequisites |

GD&T Intermediate Principles or equivalent knowledge! An interpretation level knowledge of GD&T is required to allow all participants to be successful in this class. If students do not have this level of understanding, they will not understand “why” measurements are to be taken a particular way. |

| |

The Introduction to

Dimensional Metrology Course Outline is available in PDF format. |

|

| Training Transformation |

Business Transformation |

8-Tracks Program Overview |

|

|

|

| To read about the Training Transformation, click here. |

To read about the Business Transformation, click here. |

|

|

| |

Note :  Click

on any image to zoom in. Click

on any image to zoom in. |

|

| Example Graphics from Course |

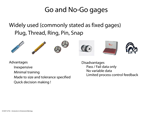

Go and No-Go Gages |

Precision Hand Tools |

|

|

|

| Non-contact 2-D Measurement Systems |

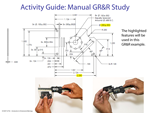

Activity Guide: Manual GR&R Study |

|

|

|

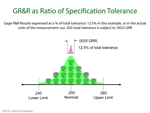

| GR&R as Ratio of Specification Tolerance |

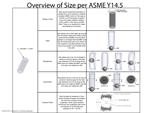

Overview of Size per ASME Y14.5 |

|

|

|

Note :  Click

on any image to zoom in. Click

on any image to zoom in. |

| Training Transformation |

Business Transformation |

GD&T Training Deployment Guide |

|

|

|

To read about the

Training Transformation, click here. |

To read about the Business Transformation, click here. |

|

|

| Example

Graphics from Course |

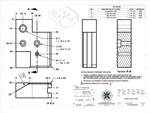

Practice Part |

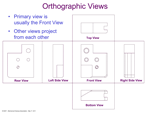

Isometric &

Orthographic Views |

|

|

| |

|

| |

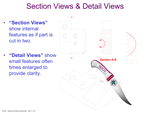

Section & Detail Views |

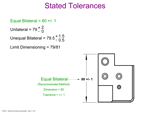

Stated Tolerances |

| |

|

|

| |

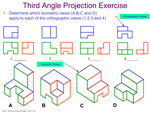

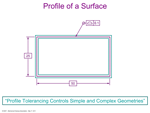

Third Angle Projection |

Profile Tolerancing |

| |

|

|

| |

|

| |

Note :  Click

on any image to zoom in. Click

on any image to zoom in. |

|