|

Level 5

GD&T -

Tolerancing Optimization & Analysis

Course Outline

|

|

Course Objective

|

To apply tolerancing optimization techniques using multiple

analytical methods to a wide variety of components and

sub-assemblies, from the very simple to the more complex

analysis.

|

|

Course Length |

2 Days (16-hours) |

|

What You Will Learn |

Tolerancing Optimization |

|

|

-

Create tolerance stack-up analysis for both plus/minus toleranced dimensions and geometric tolerances

-

Calculating boundaries using MMC, LMC and RFS Material Condition modifiers and apply transformation principles to different tolerancing scenarios to ensure optimal design intent

-

Analysis using single-segment and composite feature control frames using Position and Profile

|

|

|

Intermediate Concepts of Tolerance Analysis |

|

|

-

Derived inner and outer boundaries using floating and fixed fastener formulas

-

Create number charts for stack-up analysis using a variety of geometric tolerances, basic dimensions, resultant conditions, virtual conditions and plus and minus toleranced dimensions

-

Calculate the effects of angular stack-up contributors

-

Calculate minimum and maximum gaps for assemblies

-

Do stack-up analysis for floating and fixed fastener situations for various applications

-

Analysis and implications of different datum reference frames and implications of form errors in the analysis

|

|

|

Advanced Concepts of Tolerance Analysis |

|

|

|

|

Who Should Attend

|

Anyone with the responsibility of specifying, analyzing and

applying tolerances to mechanical components and assemblies,

tooling, equipment, fixtures or gages, or anyone requiring a

more thorough understanding of tolerancing optimization and

analysis. Specifiers and decision makers of engineering

requirements and specifications as well as specifiers of

manufacturing processes and measurement applications and anyone

doing statistical analysis of design, manufacturing or

measurement data. Engineers, designers, metrologists,

technicians, machinists, toolmakers, designers, senior

inspectors, senior technicians, statisticians and mechanical

engineers at all levels.

|

|

Prerequisites |

GD&T “Advanced Applications & Analysis.” An advanced

knowledge of GD&T is required to allow all participants to be

successful in learning tolerancing optimization and tolerance

analysis techniques. If not proficient in GD&T at an advanced

level it is strongly recommended that all individuals take or

retake the advanced course prior to the tolerancing optimization

and analysis course to ensure an optimum and proficient level of

understanding.

The

GD&T -

Tolerancing Optimization Course Outline

is available in PDF format.

|

|

|

Example Graphics from Course |

Quality Transformation |

GD&T Management |

|

|

|

|

|

|

|

|

|

Tolerance Analysis Process |

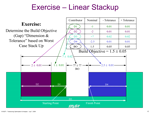

Exercise Linear Stackup |

|

|

|

|

|

|

|

|

|

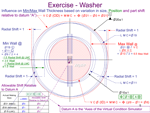

Washer Exercise |

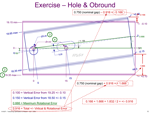

Exercise Hole & Obround |

|

|

|

|

|

|

|

|

|

Note :

Click

on any image to zoom in. Click

on any image to zoom in. |

|