|

Level 3

GD&T - Advanced Applications and Analysis

Course Outline

|

|

Course Objective

|

To provide applied working knowledge of advanced GD&T

applications involving optimization strategies for given design

applications, manufacturing methodologies and measurement

planning.

|

|

Course Length |

2 Days (16-hours) |

|

What You Will Learn |

In-Depth Analysis & Implications of Advanced Principles |

|

|

-

MMC, LMC and RFS applied to datum

features of size

-

Multiple feature patterns used to define

a single datum, and negative implications of using

“non-functional” surfaces as datum features

-

3D analysis of composite position

callouts, in relationship to multiple hole patterns defined

as a single datum

-

Calculations for determining allowable

position tolerance for floating and fixed fastener designs

-

Positioning holes and patterns of holes

at “zero tolerance” for optimizing manufacturability and

critical cost reductions

-

Positioning functional coaxial cylinders

from independent datum features -vs- to each other and

defined as compound datum features

-

Boundary principles used with profile for

non-cylindrical shapes

-

Mathematical definitions and implications

of ASME Y14.5.1M-1994

-

Surface roughness implications to

features of size and form constraints

|

|

|

Optimization Strategies in Applications & Analysis of Design, Manufacturing and Measurement |

|

|

-

Analysis and discussion of common error

implications of dimensioning and tolerancing of tooling and

functional gaging, based on product designs

-

Evaluate negative implications of common

incorrect measurement procedures on coordinate measuring

machines (CMMs) and discuss procedures to resolve / minimize

problems

-

Review and analyze “your” engineering

drawings and identify areas of negative financial

implications, address questions to provide

clarification/direction and make recommendations to optimize

design intent and achieve maximum ROI

|

|

|

Advanced Tolerancing Development within Y14.5 |

|

|

GD&T Implications to Corporate

Six-Sigma Initiatives and Product Reliability

|

|

Who Should Attend

|

Anyone requiring a greater understanding of GD&T from an

advanced applications perspective. Specifiers and decision

makers of engineering requirements and specifications as well as

specifiers of manufacturing processes, measurement applications

and statistical analysis. Engineers, designers, metrologists,

technicians, machinists, toolmakers, senior inspectors, senior

technicians, statisticians and mechanical engineers at all

levels.

|

|

Prerequisites |

GD&T Introduction & Fundamental Principles or equivalent

knowledge. It is critical that each individual reviews the

course content from the introductory course to ensure a positive

level of proficiency in all areas. If not proficient, it is

highly recommended that all individuals take or retake the

introductory course prior to the advanced course to ensure an

optimum and proficient level of understanding.

The

GD&T - Advanced Applications Course Outline

is available in PDF format.

|

|

|

Training Transformation |

Business Transformation |

GD&T Training Deployment Guide |

|

|

|

To read about the Training

Transformation, click here. |

To read about the Business Transformation, click here. |

|

|

|

Example Graphics from Course |

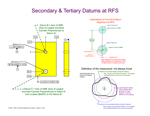

Secondary & Tertiary

Datums at RFS |

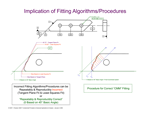

Implication of Fitting

Algorithms/Procedures |

|

|

|

|

|

|

|

|

|

Fixed Fastener |

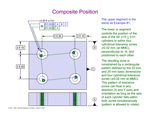

Composite Position |

|

|

|

|

|

|

|

|

|

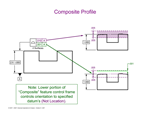

Composite Profile |

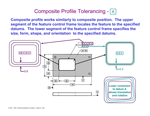

Composite Profile

Tolerancing |

|

|

|

|

|

|

|

|

|

Note :

Click

on any image to zoom in. Click

on any image to zoom in. |

|