|

Level 4

Applied Dimensional Metrology

Course Outline

|

|

Course Objective

|

To provide hands on insight to intermediate and advanced

applications and analysis of 2D & 3D measurement instruments

used to determine full compliance to mechanical drawings. Gain

insight to key error influences that can provide tremendously

different measurement results and to know how to optimize the

measurement programs to effectively reduce the measurement

error/bias. Gain insight to the strengths and limitations of

Gage Repeatability and Reproducibility (GR&R) by making visible

some key error influences that can cause significant biases in

the results and also showing how to test and correct for these

biases.

|

|

Course Length |

2 Days (16-hours) |

|

What You Will Learn |

3D Measurement |

|

|

-

Traceability of measurement to national

laboratories

-

Limitations of 1D and 2D measurements

-

Understanding key error influences and

how to test for and correct

|

|

|

Single Sensor and Multi-Sensor Coordinate Measuring Machines |

|

|

-

Video sensors, laser sensors, whitelight

interferometers and micro probes

-

Manual & automatic (DCC) CMMs, single

point touch sensors, scanning sensors and measuring arms

-

3D surface and form instruments

-

Introduction to traceable artifacts and

value of interim artifact testing

|

|

|

Methods for analyzing and interpreting data results (2D & 3D) |

|

|

-

Working with CAD and measurement data

(point clouds)

-

Analytical software – strengths &

weaknesses

-

Understanding least-squares -vs- Minimum

zone fitting

-

Understanding criticality of simultaneous

requirements within the standards (ASME, ISO, other)

|

|

|

Measurement Uncertainty/Traceability |

|

|

|

|

|

In each subject group an overview of the tools is followed by a

demonstration of best application practices and a discussion of

calibration issues and measurement uncertainty factors. Each

subject session is concluded with a hands-on lab activity and

includes discussions on understanding key error influences and

how to test for and correct them.

When practical, customer parts will be utilized during this

seminar to provide the greatest understanding of measurement

technology applicable to customer parts. |

|

|

Various parts will be utilized during

this seminar to provide the greatest understanding of

measurement technology applicable to multiple

industries. Students are encouraged to bring a part

(with CAD modal and drawing) that represents their

measurement challenges (non-confidential). |

|

Who Should Attend

|

Anyone requiring an advanced understanding of measurement

systems used for measuring mechanical components and assemblies.

Specifiers and decision makers of engineering requirements and

specifications as well as specifiers of manufacturing processes

and measurement applications and anyone doing statistical

analysis of design, manufacturing or measurement data.

Engineers, designers, metrologists, technicians, machinists,

toolmakers, designers, senior inspectors, senior technicians,

statisticians and mechanical engineers at all levels.

|

|

|

Due to the direct hands-on training in this course we limit each

session of this course to 20 participants. Limiting the number

of participants allows us to maximize the amount of time each

student will be able to have hands-on utilization of each

measurement instrument.

|

|

Prerequisites |

GD&T “Advanced Applications & Analysis.” An advanced

knowledge of GD&T is required to allow all participants to be

successful in this class. If not proficient in GD&T at an

advanced level it is strongly recommended that all individuals

take or retake the advanced course to ensure an optimum and

proficient level of understanding .

|

|

|

The

Applied Dimensional Metrology

Course Outline is available in PDF format. |

|

|

Example Graphics from Course |

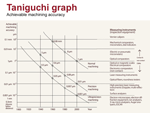

Taniguchi graph |

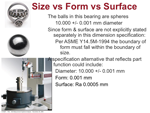

Size vs Form vs Surface |

|

|

|

|

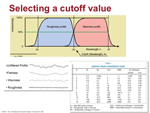

Selecting a cutoff value |

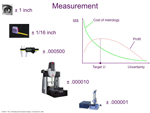

Measurement |

|

|

|

|

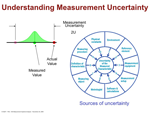

Understanding Measurement Uncertainty |

|

|

|

|

Note :

Click

on any image to zoom in. Click

on any image to zoom in. |

|